Adapting the supply chain for sustainability can be achieved through commitment and focus on product sourcing, business operations, and end of product life disposal, says Don Marshall

Product handling company, Exporta, serves some of the largest bluechip companies in the UK, from retail giants to pharmaceutical manufacturers.

Its team is dedicated to providing recyclable plastic products for materials handling, logistics, storage and distribution. This has resulted in them adopting new measures business-wide and developing a recycling initiative which will lead to a more sustainable future in the supply chain.

I want to offer some insight into how adapting the supply chain for sustainability can be achieved through commitment and focus in the following key areas:

- Product sourcing

- Business operations

- End of product life disposal

Product sourcing

How a company sources its products is a vital first step in becoming a more sustainable supplier.

Exporta sources products responsibly and the vast majority of the plastic pallets they provide for their customers are made from recycled plastic. A recent analysis of orders has shown that 98% of our pallets were made from recycled material.

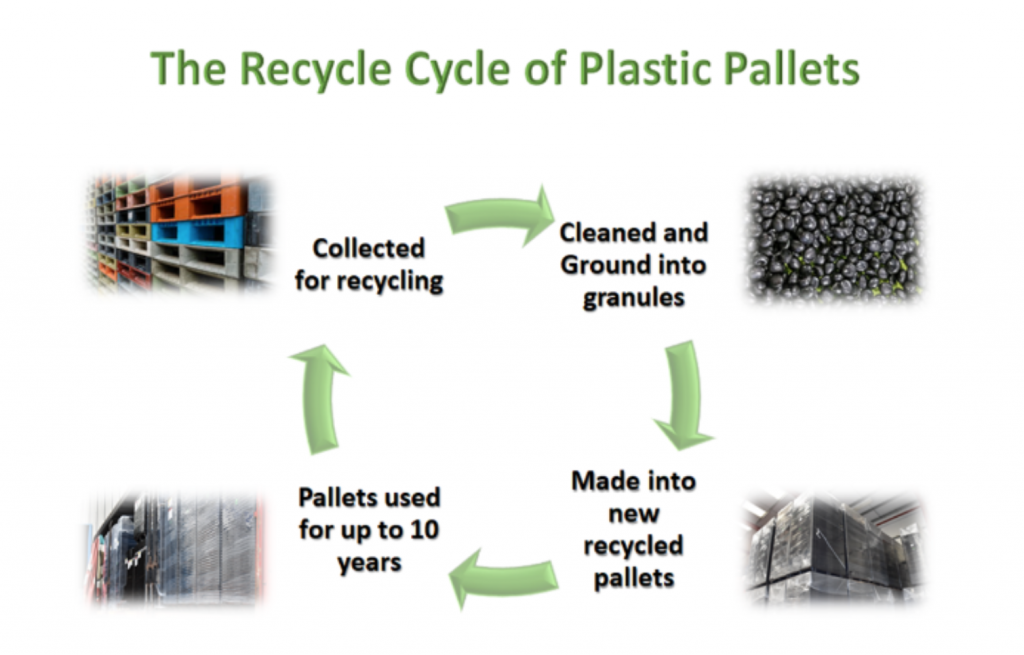

The production of these pallets takes plastic waste and creates new saleable products for the supply chain, helping to reduce pollution. All plastic pallets that we distribute are also fully recyclable at the end of their usable life, even if they’re already made from recycled material.

Offering recycled versions of products previously made with new plastic make viable and cheaper alternatives.

Operating the business

The way your business functions operationally can also be a positive step to achieving better environmental credentials.

In order to run the business in the most energy-efficient way possible, we installed solar panels to offset our carbon footprint. Exporta traces the amount of electricity generated from these solar panels, as well as the amount of plastic that is recycled through our plastic recycling scheme.

End of product life

Perhaps most importantly, adopting a recycling programme is where businesses will see the greatest results when attempting to perform sustainably.

If using plastic pallets to transport goods, as the majority of large scale companies do, being aware of the transportation methods and handling options that exist is important. The implementation of a free plastic recycling scheme for all customers is something Exporta adopted last year. The scheme is run in partnership with plastic recycling aficionados, Plastic Expert, and is run at no charge to customers.

In fact, as our Managing Director Dale Patterson explains: ‘The process is simple, if a customer has a significant supply of plastic that requires disposal, they contact us.

‘We pass the details on to our partner who arranges the collection of these items. They are then taken away to be ground down into pellets and later recycled into new plastic products such as plastic pallets.’

Adhering to environmental guidelines and consumer pressure

Adapting processes within the supply chain to promote a more sustainable future is a reality we should all embrace. The consumer pressure and an increase of environmental policies have meant that more attention is being paid to an area of the supply chain that has frankly been overlooked for too long. Almost every business has some level of desire, or requirement, to use more eco-friendly products and sustainable services where it can. However, most would be unwilling to take on additional costs to achieve these objectives. Offering recycled products as part of the service, in the product handling industry, appeals to the majority of consumers. It usually makes the products cheaper too, which is an added benefit.

Heightened scrutiny of suppliers and a need for companies to demonstrate these accreditations and sustainable practices is something that will continue to increase in demand from customers in the future. One service that Exporta’s customers repeatedly requested was support with the recycling of their plastic products; to that end, we developed, and put in place, the recycling scheme. This ensures that the plastic products supplied have a defined system and process, which allows them to be fed back into the same recycling scheme.

How to measure sustainability within your organisation

There are several ways that you can measure and quantify sustainability, and its delivery, within an organisation. The first, is to have a policy in place backed with a set of measures and KPIs. Having industry-recognised accreditations and audits such as an ISO 14001 demonstrates that sustainable practices are already established, and also helps to maintain and improve it across all areas within the business. Internal audits should also be introduced to monitor efforts.

It is easy for a business to make substantial claims concerning sustainability, and it is common to see suppliers claiming sustainability as a key strength when they have very little or no information to back this up. Businesses should provide clear action and accountability, in the shape of recognised industry accreditation.

The ISO 14001 accreditation is awarded on merit following detailed audits against strict criteria. It provides full credibility as all claims are validated by an independent authority. When looking for a sustainable supplier, you need to seek out this type of accreditation, rather than taking bold claims at face value.

Legislation can also be a powerful tool in changing habits and forcing action when it comes to sustainability in the supply chain. We only need to take the plastic bag charge as a nationwide example to see the effect it had on usage across the UK.

If we adopt a similar strategy in the supply chain and legislation was introduced that required a higher percentage of recycled plastic use, rather than new or virgin plastic, it would encourage businesses to buy more recycled products. If this legislation was extended one step further to ensure all recycled plastic was recycled again at the end of its lifespan, it would reduce plastic waste even further; as well helping to bring production costs down.

Don Marshall is Head of Ecommerce and Fulfilment at Exporta. He has 20 years’ experience, and a proven track record in multichannel retail sales and marketing, e-commerce, e-fulfilment and digital marketing for both B2B and B2C markets.